The first department of the Faculty of Agricultural Mechanization - the Department of Technical Mechanics - was organized on February 22, 1958. It was headed by the first director of the Akmola Agricultural Institute, Ph.D., cand. tech. sc. Dukhov T.G. Since April 1959, it was called the Department of Technical Mechanics and Drawing.

The staff of the department consists of 16 people, including 2 doctors of technical sciences, 1 Doctor of Pedagogical Sciences, 7 candidates of sciences, 3 PhD and 2 masters. In 2014, 3 teachers of the department entered the top 50 best scientists of the Republic of Kazakhstan. 3 teachers of the department were awarded the title "The best teacher of the University of the Republic of Kazakhstan".

Over the past five years, 6 teachers have completed internships abroad in China, Great Britain, Bulgaria, and Germany.

The main activity of the department is aimed at conducting scientific research and teaching general technical disciplines.

The department is a general engineering department, conducts classes at the faculties: technical, energy, land management, architecture and design, computer systems and vocational training in the disciplines: descriptive geometry and engineering graphics, engineering and computer graphics, automation of drawings, theoretical mechanics, applied mechanics, theory of mechanisms and machines, resistance of materials, machine parts and fundamentals of design.

Within the framework of the SPIID together with foreign partners (University of California at Davis) for the specialty 6M072400 - "Technological machines and equipment", a curriculum has been developed for the discipline design automation system in mechanical engineering.

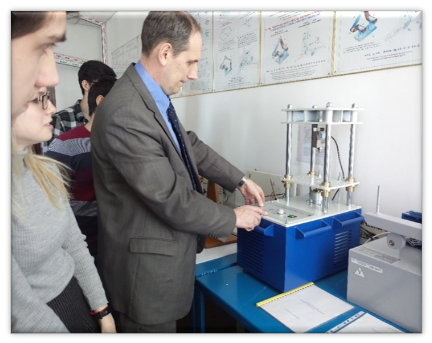

The department has 2 drawing rooms (auditorium 4402 and 4409), 4 specialized classrooms (4405 - Fundamentals of design and machine parts, 4406 - Engineering Mechanics (Statics, Dynamics), 4407 - Computer-aided design of mechanisms, 4511 - Mechanics of materials), 2 classrooms (auditorium 4411 and 4412), a computer classroom (auditorium 4410), a Design bureau (auditorium 4201) and a research laboratory.

|

Educational and laboratory stand "Determination of support reactions of beams" ELB-161.004.03

|

Educational and laboratory stand "Determination of the coefficient of friction"

|

|

Laboratory stand STC-13.01.B "Applied Mechanics"

|

Educational and laboratory stand "Study of a flat system of descending forces" ELB - 161.016.01

|

|

Automated laboratory complex "Gear transmission machine parts"

|

Set of educational and laboratory equipment "Cutting of involute teeth by running-in "

|

|

Automated laboratory complex "Research of mechanical connections" DM-RM-MS-5S

|

Laboratory stand "Determination of the efficiency of a mechanism with a rocking rocker LLS - TMM - 01"

|

|

|

|

|

|

|

As a result of the implementation of funded and initiative research by the teaching staff of the department over the past 5 years, they have been developed and put into production:

- chisel-fertilizer for applying the main dose of mineral fertilizers with zero tillage (head Nukeshev S.O.);

- flat-cutter-ripper-slitter (head Eskhozhin D.Z.);

- software and technical means of automated technological process of differentiated application of seeds and fertilizers in the adopted positioning system (head Nukeshev S.O.).

In recent years, scientific work at the department has been carried out on the topic "Improvement of agricultural machinery and technology for the zone of Northern Kazakhstan" under the state registration number 0112RK02803. The doctors of technical sciences, professors Eskhozhin D.Z. and Nukeshev S.O., Ph.D., associate professors Akhmetov E.S., Gorbunov B.N. and senior teachers Tokushev M.K., Tleumbetov K.M., assistant Kusainov R.K., undergraduates and doctoral students of the department work on this topic.

The staff of the Department actively participated in the competition of projects of the Ministry of Education and Science of the Republic of Kazakhstan for grant funding for 2015-2017. As a result, a first scientific grant was won in the amount of 20,000,000 tenge per year, on the topic "Development of a new technology and technical means for intra-soil differentiated three-layer application of mineral fertilizers. (head - Doctor of Technical Sciences, Professor S.O. Nukeshev).

Within the framework of grant financing under the budget program 217 of the Ministry of Education and Science of the Republic of Kazakhstan for 2018-2020:

"Development of an automated grain and grass seeder for differentiated direct sowing of agricultural crops under cover crops and in the sod with simultaneous application of mineral fertilizers" (PhD, Prof. Nukeshev S.O.). The amount of fundong is 30 million.

Within the framework of program-targeted financing of the Ministry of Agriculture of the Republic of Kazakhstan:

Subproject "Differentiation of technological processes in the cultivation of agricultural crops in the precision farming system based on the modernization of used equipment and information technology" (PhD, Prof. Nukeshev S.O.). The amount of the finding is 18 million.

The subproject "Transfer and adaptation of technologies for point farming in the production of crop production on the principle of "demonstration farms" (polygons) of the North Kazakhstan region for 2018-2020. (Hand. Doctor of Technical Sciences, prof. Nukeshev S.O.). The amount of funding is 114 million.

Commercialization project funded by JSC "Science Foundation" of the Committee of Science of the Ministry of Education and Science of the Republic of Kazakhstan, on the topic "Organization of production of technical means for the implementation of technologies of differentiated application of mineral fertilizers, ensuring the preservation of soil fertility and increasing yields", the amount of funding - 230 million.

Over the past 8 years, more than 50 copyright certificates for inventions, patents, preliminary and innovative patents of the Republic of Kazakhstan have been obtained. Over 200 scientific articles and recommendations for production have been published.

The department is headed by Doctor of Philosophy (PhD) Tokushev Masgut Hairzhanovich.

All achievements of the faculty are the result of the department staff productive work. The first chair of the faculty, Engineering Mechanics Department was established on 22.03.1958. by T. G. Dukhov, Сandidate of technical sciences, senior researcher, who was the first head of the Department. In April 1959 it was divided into two departments: Engineering Mechanics and Drawing Department (Kupershtokh L.N., Сandidate of technical sciences - the Head of the Department) and the Department of Agricultural Production Mechanization (Bock N.B., senior lecturer - the head of the Department).

Dukhov T. G. headed Metal Technology and Machine Repair Department, that was organized in July 1959.

In October 1961 there was a new division of the departments: the Department of Engineering mechanics and drawing was divided into the Descriptive geometry and graphics Department (Kupershtokh L.N., Head of the Department) and the Strength of materials and machine parts Department (was Plisuchenko A.A., Head of the Department, associate professor).

The heads of the department: L.M. Kupershtokh, Candidate of technical sciences, Associate professor (in 1961-1976); Yeskhozhin D.Z., Candidate of technical sciences, Associate professor (in 1976-1987), T.K.Nurgaliyev, Candidate of technical sciences, Associate professor (in 1987-1997).

Over the years, T.K.Nurgaliyev, Сandidate of technical sciences, Associate professor, Yeskhozhin D.Z., Сandidate of technical sciences, Associate professor, Fedorov A.K., Сandidate of technical sciences, Associate professor, and V.G.Naumenko, A.P. Kirilenko, Mosunov V.I., Fabritskaya L.F., Tuzhilkin I.V. (Senior lecturers), Shalamova V.A., Bondar A.I., Samoilov Y.I., Zhelnina L.N., Aduov M.A. (Teaching assistants), Prilipuhina L.P., Sirabidze R. (Lab technicians) worked at the Department. The Department had classes at the agricultural production mechanization faculty, electrification of agriculture, engineering and pedagogical, and architectural faculties. Such disciplines as descriptive geometry, technical drawing, engineering graphics and theory of mechanisms and machines were taught by the Department academic staff. The department had two drawing halls, laboratories of the theory of mechanism and machines, and R & D laboratories. They are equipped with visual aids, models, mechanisms, R & D laboratory is also equipped respectively. Department academic staff prepared and published more than 25 methodical papers, 4 textbooks and 6 tutorial manuals (Authors are Yeskhozhin D.Z., Fedorov A.K., Tuzhilkin I.V., Nurgaliyev T.K.). It made possible to teach in accordance with modern requirements. Classes were taught on a modular technology, and knowledge assessment was based on a ranking system. The research work was carried out in two directions: up to 1977, "Problems of Higher Education", then on "Improving the working details of machines with soil protection technology." Since 1977, R & D has been carried out primarily by economic contracts.

According to the scientific research results at the department, 5 PhD theses were prepared (Baitlesov K., Aduov M. A, Goncharova L. N., Nurgaliyev T. K., Nukeshev S. O.), 31 author's certificates for inventions were obtained, 193 scientific articles were published. Every year, 20-25 reports are prepared for student scientific conferences, and half of them take prizes. Two papers became winners of the republican and one-union competitions. Over the past period, the department academic staff has been trained in the leading universities of the USSR-MSU, MARKHI, Kiev and Tomsk PTI.

The strength of materials and machine elements department. A.A. Plisuchenko (in 1961-1966); V.N. Hwang, Сandidate of technical sciences (in1966-1969); T.K.Nurgaliyev (in 1969-1970), V.M.Gurevich, Сandidate of technical sciences (in 1970-1981); A.M.Trebler, Сandidate of technical sciences (in 1981-1992), K.A. Koyshubaev, Candidate of technical sciences (in 1992-1997) worked as the Head of the Department.

In different years at the department worked associate professors Koishubaev K. A., Gurevich V. M., Trebler A.M., Bondarenko V. I., Grishin A. N., Syzdykov Zh. A., senior teachers Filippova R. E., Bazilevskaya E. N., Zavodnov V. S., Rudinsky S. G., Parfenov A. G., Brimaer V. A., L. I. Voronkova, T. A. Nazarenko, assistants Uskenbaev A. K., Zhakipov G. T., Bekisheva A.D., B. T. Baeshev, laboratory assistants Tikhonyuk N. P., Kogut V. The department taught classes at the faculties of Agricultural Mechanization, Agricultural Electrification and Engineering faculty following disciplines: resistance of materials, machine parts, lifting and transport machines, technical mechanics and theoretical mechanics. The department has 4 specialized classrooms equipped with modern equipment and visual aids. Laboratory classes are provided with methodological developments of the department and one textbook (authors Gurevich V. M., Koishubaev K. A.), research directions: improving the reliability of agricultural machines and biomechanics. The main part of scientific research is conducted under economic contracts, and some of their results are implemented in factories and agricultural enterprises of Northern Kazakhstan. According to the results of the research, 7 PhD theses were defended, 2 of them (Bondarenko V. I., Koishubaev K. A.) were prepared on-the-job. Employees of the department are the authors of 5 inventions, 1 patent and more than 230 scientific publications. At the NSO conference, the department prepares about 20 reports annually, some of them take prizes.

In 1997, the Departments of Descriptive Geometry and Graphics and the Department of Resistance of Materials and Machine Parts merged into one Department of Technical Mechanics, headed by Ph. D., Associate Professor Nurgaliev T. K. (1997-1999), Ph. D., Associate Professor Gorbunov B. N. (2000-2012). Currently, the head of the department Ph. D., Associate Professor Akhmetov E. S. The current composition of the department: Ph. D., Professors Eskhozhin D. Z., Nukeshev S. O., Musalimov T. K., Ph. D., associate Professors Akhmetov E. S., Gorbunov B. N., Candidate of Technical Sciences, senior teachers Aubakirov B. U., Suyundikov A. A., Mamyrbaeva I. K., Kubentaeva G. K., PhD Doctor Zhaksylykova Z. S., Tokushev M. K., senior lecturer teachers Bektegenova A. S., Martych S. P., Tleumbetov K. M., clerk Satybaldina Z. S., senior laboratory assistant Shmer M. V.

Along with providing high-quality training of specialists, the staff of the department attaches great importance to research work, its effectiveness. The most important results were put into production and completed with the preparation of dissertations. So, during the existence of the department, its employees have defended 2 doctoral and 4 candidate theses. (Doctoral dissertations Eskhozhin D. Z., Nukeshev S. O., candidate's dissertations Gorbunov B. N., Syzdykov Zh. A., Nukeshev S. O., Akhmetov E. S.). The steady state of the faculty of the department increased from 37.4 to 70 %.

More than 200 copyright certificates for inventions, patents, preliminary and innovative patents of the Republic of Kazakhstan were obtained. Over 600 scientific articles and recommendations for production have been published. The greatest contribution to the organization of research and the creation of a scientific school at the department was made by Professor Eskhozhin D. Z. Thus, the works of Eskhozhin D. Z. on the development of effective working bodies of agricultural machines are considered to be leading in this field.

Doctor of Technical Sciences, Professor S. O. Nukeshev has achieved notable results in his research areas - development of machines for intra-soil differentiated application of mineral fertilizers in the system of precision agriculture, etc. The department conducts a significant part of its research under grants from the Ministry of Education and Science and the Ministry of Agriculture of the Republic of Kazakhstan.

As a result of the implementation of funded and initiative research there were developed and put into production by the faculty of the department over the past 10 years:

- design documentation and a prototype of a machine for intra-soil application of mineral fertilizers and pre-sowing tillage (head S. O. Nukeshev);

- technology and machine for in-ground application of mineral fertilizers in the coordinate farming system (head S. O. Nukeshev);

- recommendations on the differentiated use of mineral fertilizers in the precision farming system (head of the department S. O. Nukeshev);

- information technology of differentiated application of mineral fertilizers and a cultivator-fertilizer with a central seeding system for its implementation (head Nukeshev S. O.);

- chizel-fertilizer for applying the main dose of mineral fertilizers at zero tillage (head Nukeshev S. O.);

- ploskorez-ripper-schelevatel (head Eskhozhin D. Z);

- software and technical means of the automated technological process of differentiated application of seeds and fertilizers in the adopted positioning system (head S. O. Nukeshev).

In recent years, scientific work at the department is carried out on the topic "Improvement of agricultural machinery and technology for the zone of Northern Kazakhstan" under the state registration number 0112RK02803. Participants of the research work are Doctor of Technical Sciences, Professors Yeskhozhin D. Z. and Nukeshev S. O., Candidate of Technical Sciences, associate professors Akhmetov E. S., Gorbunov B. N. and senior teachers Tokushev M. K., Tleumbetov K. M., assistant Kusainov R. K., undergraduates and doctoral students of the department.

The staff of the department actively participated in the competition of projects of the Ministry of Education and Science of the Republic of Kazakhstan for grant funding for 2015-2017. As a result, 1 scientific grant was won in the amount of 20,000,000 tenge per year, on the topic " Development of a new technology and technical means for intra-soil differentiated three-layer application of mineral fertilizers. (head - Doctor of Technical Sciences, Professor S. O. Nukeshev).

Projects within the framework of grant funding under the budget program 217 of the Ministry of Education and Science of the Republic of Kazakhstan for 2018-2020 were gained: "Development of an automated grain-and-grass seeder for differentiated direct sowing of agricultural crops under cover crops and in sod with simultaneous application of mineral fertilizers" (Doctor of Technical Sciences, Professor S. Nukeshev). The amount of the financing - 30 million.

Projects within the framework of program-targeted financing of the Ministry of Agriculture of the Republic of Kazakhstan were gained:

Subproject "Differentiation of technological processes in the cultivation of agricultural crops in the system of precision agriculture based on the modernization of the equipment used and information technology" (Doctor of Technical Sciences, Professor S. Nukeshev). The amount of financing - 18 million.

Subproject "Transfer and adaptation of technologies for point farming in the production of crop production on the principle of "demonstration farms" (landfills) of the North Kazakhstan region for 2018-2020. (Doctor of Technical Sciences, Professor S. Nukeshev). The amount of financing – 114 million.

Commercialization project funded by JSC "Science Foundation" of the Committee of Science of the Ministry of Education and Science of the Republic of Kazakhstan. On the topic "Organization of production of technical means for the implementation of technologies of differentiated application of mineral fertilizers that ensure the preservation of soil fertility and increase productivity", the amount of financing - 230 million.

The results of the research were implemented in the economic entities of Northern Kazakhstan.

The above-mentioned scientific achievements indicate the high potential of the department's scientists. The scientific and practical significance of the research carried out by the Faculty of the Department is that the scientific foundations of mechanization, automation of agricultural production-tillage, sowing, intra-soil differentiated application of mineral fertilizers in the system of precision agriculture have been created. On the basis of methodically reliable experimental material, the results of a comparative assessment of new technological principles in the conditions of Kazakhstan were obtained. The use of the space navigation system (GPS, GLONASS) to determine the uneven distribution of batteries and the differentiated application of mineral fertilizers on the electronic map indicates the compliance of the conducted research with the world level of science.

The continuation and development of these studies in the following years will allow the formation of a new scientific direction in agricultural engineering and the application in the agro-industrial complex of Kazakhstan of environmentally friendly highly qualified information technology for the production of grain and vegetable crops, based on the achievements of automation, informatization and space technologies.

The high scientific achievements of the department's scientists were noted by various public and research organizations, so 2 professors were elected full members of various academies:

Yeskhozhin D. Z.-full member of the ASKHN of the Republic of Kazakhstan, Nukeshev S. O.-full member of the ASKHN of the Republic of Kazakhstan, corresponding member of the National Academy of Sciences of the Republic of Kazakhstan.

Two lecturers, Yeskhozhin D. Z. and Nukeshev S. O., were awarded the high title of "Best teacher of the Year". Yeskhozhin D. Z. was awarded the government award "Eren enbegi ush'in".

Three lecturers of the department (Yeskhozhin D. Z., Nukeshev S. O., Akhmetov E. S.), in 2015 were included in the top 50 best lecturers of Kazakhstan.

Department main research developments

Engine – Flat cutting-ripper-sheather

Development manager is D.Z.Yeskhozhin, Сandidate of technical sciences, professor, and academician of Academy of agricultural sciences of Kazakhstan

|

|

Cannon flat cutting - ripper-sheather, which can operate in three modes - flat cutting, flat cutting-ripper and flat cutting-ripper-sheather; sheather knives at the bottom of the furrow cut slits that contribute to the accumulation of moisture, intensification of water and air processes, biochemical, and metabolic and regenerative processes, lifting the groundwater to the root system of plants in the summer dry season and eliminate spring and summer precipitation runoff in lowland. Loosening rates on moisture-accumulating increased for 1,4-1,6 times in comparison with the serial moisture-accumulating. |

Machines for intra differentiated application of mineral fertilizers

S.O.Nukeshev, Development manager, Doctor of Engineering, professor, Member of the Academy of agricultural sciences of the RK, Corresponding Member of NAS RK

Chisel-fertilizer

|

|

Chisel-fertilizer provides soil tillage to a depth of 5.6 ... 34.8 cm, fertilization with wide sloping tape of 32 ... 35 cm, and the uneven distribution of fertilizer across the width of 7,8-14,8%. Doze of fertilizer 50-480 kg / ha, the uneven application rates of 8-12%. |

Cultivator - fertilizer with CMC

|

|

|

Cultivator fertilizer with CMC allows you to differentiate making dose of 50 to 450 kg / ha at the time of the transition period to 3-3.5 seconds and reduces uneven application of operating grasp by 20-22%, increases the width of fertilizer line by 30-35%. Differentiated application of mineral fertilizers considering initial non-uniformity of nutrients distribution in the soil based on the original non-uniformity of nutrients distribution in the soil will increase the return of phosphorus fertilizers up to 18.5 kg of grain for 1 kg of active compound fertilizers while the regulatory payback of 8-10 kg.

Cultivator-fertilizer based stubble seeders

|

|

Cultivator fertilizer based on BES 2.0 allows to differentiate dose application from 12 up to 408 kg / ha and increase the width of the sieving fertilizer for more than 3 times to the depth of 8 cm. |

Technical means of monitoring and control of the metering system of the machine

|

|

|

Developed technical tools for monitoring and control of the metering system of the machine (BKU DSM) allows you to automatically monitor the location of the unit on the field, the parallel driving, lateral deflection and control the flow rate of seeds and fertilizers for the speed and location of the unit in accordance with the electronic cards tasks. It also has such functions as measuring the distance traveled; clarifying areas of farmland; treated area measurement; field layout at rectangular stints; obtaining primary geodetic information for making plans for the fields and refinement of geometrical parameters of agricultural land.

Projects within the framework of grant funding under the budget program 217 of the Ministry of Education and Science of the Republic of Kazakhstan 2018-2020 were gained:

An experimental sample of the seeder was developed. Scientific novelty - the laws of interaction of the sealing working body with the soil. The seeder provides sowing of hard-to-loose grass seeds at depths of 1.8-6 cm with uneven and unstable seeding in the range of 1-6 % and differentiated fertilization at depths of 8-12 cm. The economic effect of the introduction of the seeder is 4.8 thousand tenge/ha. The results of the research can be used by specialists in creating new and improving existing technical means for sowing.

|

|

|

Projects as part of the program-targeted financing of the Ministry of Agriculture of the Republic of Kazakhstan for 2018-2020: there were prepared project within the framework of the Scientific and Technical program "To develop a system of precision farming of agricultural crops with the use of elements of cultivation technology, differentiated nutrition, plant protection products and equipment for cost-effective production using information technology tools based on a comparative study of various cultivation technologies in the north Kazakhstan" under the event "Differentiation of technological processes in the cultivation of agricultural crops in the precision farming system based on the modernization of the equipment and information technology used".

The results of the work are a manufactured model of a universal control system for the differentiation of fertilizer application, the results of laboratory and field studies to clarify the main parameters of the executive mechanism of the model. The developed system of control and dosing monitoring has the transient characteristics characteristic of the aperiodic link with a delay time of 2.9-3.1 s and provides automatic change of fertilizer doses with a transition time of 0.9-9 s.

|

|

|

To develop an experimental sample of chisel-fertilizer for intra-soil differentiated application of the main doses of mineral fertilizers in the system of precision agriculture within the framework of the project, the scientists of the department developed a chisel-fertilizer for the intra-soil differentiated application of the main doses of mineral fertilizers in the precision farming system (head of the subproject, Doctor of Technical Sciences, prof. Nukeshev S. O.). Chizel-fertilizer provides deep loosening of the soil up to 30-35 cm and uniform differentiated distribution of the main doses of mineral fertilizers (up to 400 kg/ha) inside the soil with an inclined tape to the depth 6...8, 16...18, 23...25 see according to task-maps-prescriptions.

|

|

|

The project of commercialization funded by JSC "Science Foundation" of the Committee of Science of the Ministry of Education and Science of the Republic of Kazakhstan. The topic "Organization of production of technical means for the implementation of technologies of differentiated application of mineral fertilizers that ensure the preservation of soil fertility and increase productivity»

|

|

|

There are 17 academic staffs at the department, including 3 doctors of sciences, 7 candidates of sciences and 2 PhD.

Departmentmain research areas:

The research work of the department was carried out by a research group headed by Doctor of Technical Sciences, professors Yeskhozhin D.Z, and Nukeshev S.O.

In 2006-2008, within the framework of Ministry of Agriculture of the Republic of Kazakhstanbudget program, studies were carried out on the topic "Development of technology and machines for the intrusion of mineral fertilizers in the coordinate agricultural system". Based on the results of the study, a technology was developed for differentiated intrasoil application of mineral fertilizers and a fertilizer cultivator based on the SZS-2,0 seeder. The investigation was implemented in JSC "Akmola-Phoenix".

In 2007-2009, within the framework of Ministry of Agriculture of the Republic of Kazakhstanbudget program, research was conducted on the topic "Development of information technology and technical means for the differential application of mineral fertilizers using the space navigation system (GPS, GLONASS). The prototypes were introduced in "Agroprom Service ES" LLP in Astana, "TPK KazAgros" LLP of Kostanay region.

In 2012-2013, within the framework of technological business incubation, a research work on the topic "Introduction of Information Technology for Differentiated Applications of Mineral Fertilizers in the Precision Farming System" was gained. A prototype has been manufactured.

In 2012-2014, research was conducted on the topic "Development of software and technical means for monitoring and controlling the automated technological process of differentiated application of seeds and fertilizers in the adopted positioning system." A prototype of a grain-grinding machine with a control and controlling unit for the machine's dosing system was made.

In 2015-2017, within the framework of Ministry of Education and Science of the Republic of Kazakhstangrant funding, studies were carried out on the theme "Development of a new technology and a technical tool for intrasoil differentiated three-layer mineral fertilization". Based on the results of the study, an experimental sample of a fertilizer cultivator for an intrasoil differentiated three-layer application of mineral fertilizers was developed.

In 2018-2020, within the framework of Ministry of Education and Science of the Republic of Kazakhstangrant funding, research was conducted on the project "Development of an automated grain and grass seeder for differentiated direct sowing of agricultural crops under cover crops and in sod with simultaneous application of mineral fertilizers". Based on the results of the study, an experimental sample of the seeder was developed. The seeder provides sowing of hard-to-loose grass seeds at depths of 1.8-6 cm with uneven and unstable seeding in the range of 1-6 % and differentiated fertilization at depths of 8-12 cm.

Research projects within the framework of the program-targeted financing of the Ministry of Agriculture of the Republic of Kazakhstan for 2018-2020:

Subproject "Differentiation of technological processes in the cultivation of agricultural crops in the precision farming system based on the modernization of the equipment used and information technology". Based on the results of the study, a model of a universal system for managing and controlling the differentiation of fertilizer application was made. The developed controlsystem and dosing monitoring has transient characteristics of the aperiodic link with a delay time of 2.9-3.1s and provides automatic change of fertilizer doses with a transition time of 0.9-9 s.

Subproject " Transfer and adaptation of technologies for point farming in the production of crop production on the principle of "demonstration farms" (landfills) of the North Kazakhstan region for 2018-2020. Based on the results of the study, a chisel-fertilizer was developed for the intra-soil differentiated application of the main doses of mineral fertilizers in the precision farming system (head of the subproject, Doctor of Technical Sciences, prof. Nukeshev S. O.). The chisel-fertilizer provides deep loosening of the soil up to 30-35 cm and uniform differentiated distribution of the main doses of mineral fertilizers (up to 400 kg/ha) inside the soil with an inclined tape to the depths 6...8, 16...18, 23...25 see according to task-maps-prescriptions.

Based on the results of scientific research, the research group published 3 monographs, 10 articles in peer-reviewed publications included in the Web of Science databases, 16 articles in peer-reviewed publications included in the Scopus resources, 20 articles in rating publications included in the RSCI resources, as well as 39 articles in scientific journals included in the list of publications recommended by the CCSS, and 27 patent protection documents for the invention.

Currently, Ministry of Education and Science of the Republic of Kazakhstan,Science Committeethe commercialization project, funded by JSC "Science Foundation", is being implemented. On the topic "Organization of production of technical means for the implementation of technologies of differentiated application of mineral fertilizers that ensure the preservation of soil fertility and increase productivity".

The department has four cooperation agreements with organizations from Belarussia, Poland, Slovakia, Russia. Contracts on creative collaboration and book exchange with the Belarussian State Agrarian University, Russian Academy of Agricultural Sciences and the All-Russian Research Institute of Agricultural Mechanization.

The Head of Space Monitoring of Laboratory Senior Researcher of GNU VIM, d.t.s Leachman G.I and the first vice-rector of the Belarusian State Agrarian Technical University, c.t.s., associate professor N.N.Romanyuk take part in the realization of scientific potential of the department. They consult the developments of technical means for monitoring and control of the metering system.

Staff of the department undertook advanced training courses .Senior teacher Mamyrbaeva I.K had advanced training courses from 01-13 June 2014 in the UK in Norwich city. From 28-13 July 2014, Professor of the Department Nabi Y.A. undertook advanced training courses in “International Academy fin management und Technologie University”, Germany, Dusseldorf. In 2015, Professor S.O Nukeshev undertook advanced training according within «Bolashak" Program in the city of Leicester, UK.

Educational work with students is linked with learning activities and it is conducted according to the universityeducational work approved program, developed taking into account the model of innovative development.

The aim of the educational process is the comprehensive harmonious development of student's personality. It has the following directions: bringing-up of positive personality; development of an active life position; ability to self-education, and self-control; education of self-esteem; development of a sense of pride for the development and prosperity of the Republic of Kazakhstan; spirituality and morality;physical perfection; culture of behavior; environmental culture.

The Engineering Mechanics Department has 4 curatorial groups, the curators are: Mamyrbaeva I. K., Sekerbek A.M., Zhaksylykova Z. S., Kubentaeva G. K.

Within the framework of socio-political, patriotic and legal education, curatorial hours dedicated to the state holidays of the Republic of Kazakhstan are held.

Each curator works with group according to the educational workplan. Educational work with students is carried out in the following areas: cultural, socio-political, legal, patriotic, spiritual and moral, physical and labor education, promotion of a healthy lifestyle. Curators use effective methods of working with students for professional development and self-realization of the individual, the formation of the need for self-education throughout the educational process.

Students are engaged in scientific work;they annually make presentations at the conference "Seifullin readings".

Students take an active part in the annual events: "The first student autumn", the spring festival "Nauryz", the inspection of amateur performances," Student Spring", sports competitions. They also take prizes at subject Olympiads. The curators, together with the curatorial groups, actively participate in the sports and and health life of the university and the city: a student of the TMO-18-11 group KoishybayUlastook 2nd place in Grampling, AyazovAmal participates in competitions in the national team in football, Nur-Sultan,a student of the TMO-19-08 group TursynbayArshyn took 1st place in Athletics "Orlyonok".

Many students are members of the university cheerful and resourcefulclubteam.

Academic staff of the department: Mamyrbaeva I. K., Martych S. P., Zhaksylykova Z. S. are the best curators at the university.

Students and academic staff of the department take an active part in all events held at the faculty and at the university (public holidays, sports competitions, months for the prevention of offenses, drug addiction and religious extremism).

Engineering Mechanics Department The Subject Olympiads and competitions Information

|

Discipline title |

Student’s name |

Position |

Competition name, organization |

|

2021– 2022 academic year |

|||

|

Machine parts and design basics |

Zhampeiis S.D. |

1 |

All-Russian Olympiad in the discipline "Machine parts" |

|

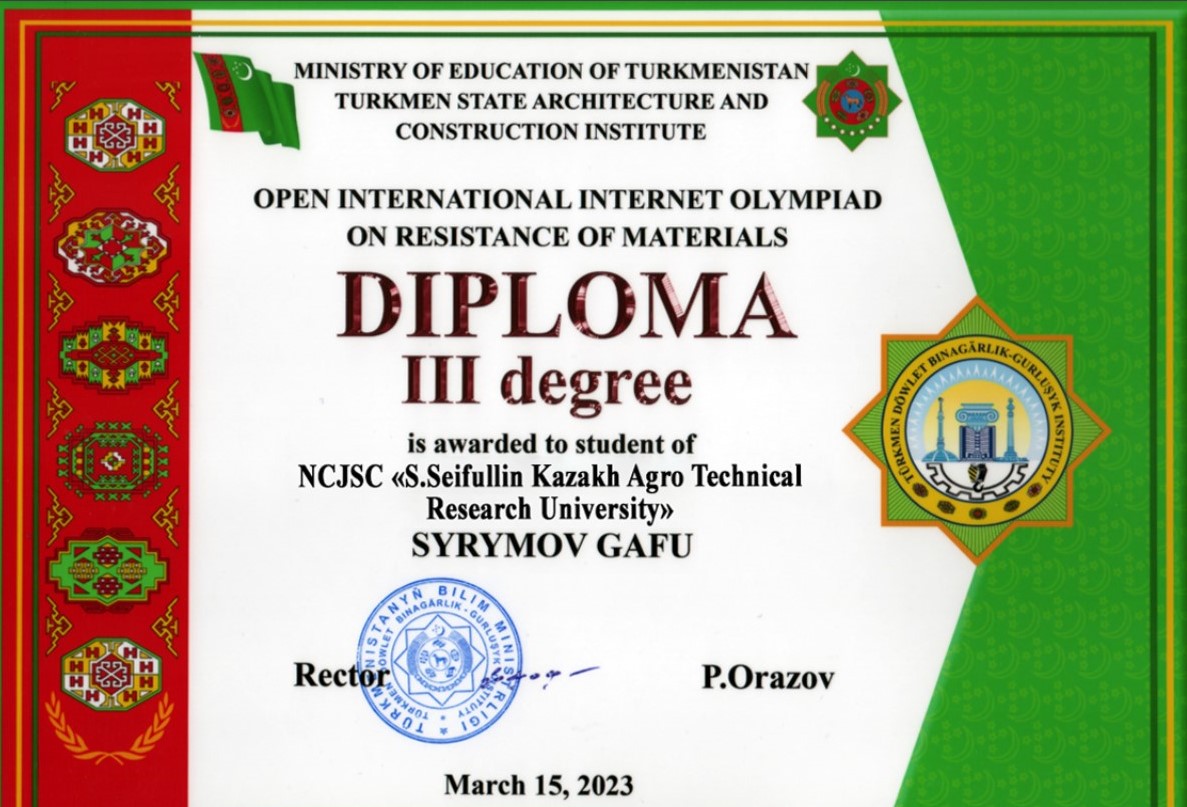

2022– 2023 academic year |

|||

|

Applied Mechanics |

Syrymov G. T. |

3 |

International Online Olympiad on Materials Resistance |

|

Automating the execution of drawings |

Shmer R.A. |

2 |

All-Russian Olympiad in the discipline "Engineering and computer graphics" |

|

Applied Mechanics |

Veliullayeva Z.R. |

2 |

All-Russian Olympiad in the discipline "Technical Mechanics" |

|

Название дисциплины |

Ф.И.О. студента |

Занятое место |

Место проведения |

|

2013 – 2014 учебный год |

|||

|

Начертательная геометрия

|

Жарылкасым К. Орынбасар Е.

|

3

|

Республиканская студенческая олимпиада МОН РК, КазНТУ 20.04.2014 |

|

2014– 2015 учебный год |

|||

|

Начертательная геометрия

|

Ким С. Кайдар С.

|

2

|

Республиканская студенческая олимпиада МОН РК, КазНТУ 15.04.2015 |

|

2015– 2016 учебный год |

|||

|

Детали машин и основы конструирования

|

Абылгазин Е. |

3 |

Республиканский конкурс и олимпиада «Лучшая курсовая работа» 28.03.2016 |

|

Начертательная геометрия

|

Кайыржанова А. Саржанова А.

|

2 |

Республиканская студенческая олимпиада МОН РК, КазНТИУ 09.04.2016 |

|

2018– 2019 учебный год |

|||

|

Детали машин и основы конструирования |

ЕржанұлыМақсат |

1 |

Республиканская студенческая олимпиада ГУ им. Шакарима, г. Семей 06-08.04.2019 |

Работы студентов участвовавшие в международном конкурсе по 3D моделированию

|

Название дисциплины |

Ф.И.О. студента |

Название конкурса, организация |

|

2018– 2019 учебный год |

||

|

Детали машин и основы конструирования |

Абдиханов С. |

Будущие Асы цифрового машиностроения по 3D моделированию, Фирма «АСКОН» |

|

Детали машин и основы конструирования

|

Утепбаева Ш |

Будущие Асы цифрового машиностроения по 3D моделированию, Фирма «АСКОН» |

|

2019– 2020 учебный год |

||

|

Детали машин и основы конструирования

|

Абдиханов С. |

Будущие Асы цифрового машиностроения по 3D моделированию, Фирма «АСКОН» |

|

Детали машин и основы конструирования

|

Бекалиев А |

Будущие Асы цифрового машиностроения по 3D моделированию, Фирма «АСКОН» |

|

Disciplinetitle |

Student’s name |

Position |

Location |

|

2013 – 2014 academicyear |

|||

|

Descriptive geometry |

Zharylkasym K. Orynbassar Е. 3 |

3

|

Republican student olympiadMES RK KazNTU 20.04.2014 |

|

2014– 2015 academicyear |

|||

|

Descriptive geometry |

Kim S. Kaydar S. |

2

|

Republican student olympiadMES RK KazNTU 15.04.2015 |

|

2015– 2016 academic year |

|||

|

Machine components and design basics |

Abylgazin E. |

3 |

Republican competition and Olympiad «Best thesis» 28.03.2016 |

|

Descriptive geometry |

Kairzhanov A. Sarzhanova A. |

2 |

Republican student olympiadMES RK KazNTRU 09.04.2016 |

|

2018– 2019 academicyear |

|||

|

Machine components and design basics |

MaksatYerzhanuly |

1 |

Republican Student Olympiad of the ShakarimState University, Semey 06-08.04.2019 |

Students’Works participated in the international competition for 3D modeling

|

|

|

|

|

Disciplinetitle |

Student’s name |

Competitionname, organization |

|

2018– 2019academicyear |

||

|

Machine components and design basics |

Abdikhanov S. |

Digital Engineering Future Aces in 3D Modeling, The "ASKON" company |

|

Machine components and design basics |

UtepbaevaSh. |

Digital Engineering Future Aces in 3D Modeling, The "ASKON" company |

|

2019– 2020 academicyear |

||

|

Machine components and design basics |

Abdikhanov S. |

Digital Engineering Future Aces in 3D Modeling, The "ASKON" company |

|

Machine components and design basics |

Bekkaliev A. |

Digital Engineering Future Aces in 3D Modeling, The "ASKON" company |

10000, Republic of Kazakhstan,

Nur-Sultan, A.Moldagulova street 27D,

building №4, cabinet 4304

тел.: +7 (7172) 397-409, Е-mail: techmechanics@kazatu.kz